Abstract

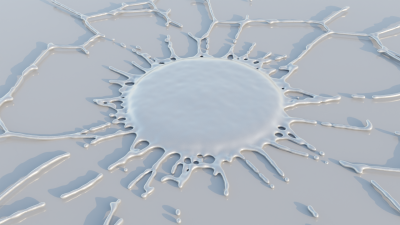

The properties of a thermally sprayed coating, such as its durability or thermal conductivity depend on its microstructure, which is in turn directly related to the particle impact process. To simulate this process we present a 3D Smoothed Particle Hydrodynamics (SPH) model, which represents the molten droplet as an incompressible fluid, while a semi-implicit Enthalpy-Porosity method is applied for modeling the phase change during solidification. In addition, we present an implicit correction for SPH simulations, based on well known approaches, from which we can observe improved performance and simulation stability. We apply our SPH method to the impact and solidification of Al2O3 droplets onto a substrate and perform a comprehensive quantitative comparison of our method with the commercial software Ansys Fluent using the Volume of Fluid (VOF) approach, while taking identical physical effects into consideration. The results are evaluated in depth and we discuss the applicability of either method for the simulation of thermal spray deposition. We also evaluate the droplet spread factor given varying initial droplet diameters and compare these results with an analytic expression from previous literature. We show that SPH is an excellent method for solving this free surface problem accurately and efficiently.